To make reduced greenhouse gas emissions a shared lever for cost savings and productivity: this is the vision VINCI Energies is pursuing in its facility management business, moving to make decarbonisation targets and tools key components in all its contracts. Pierre-Yves Dehaye, Facility Management Managing Director – South-Centre-East Region, at VINCI Energies in France, provides the details.

Environmental transition is an explicit priority for many large businesses. What levers can be applied through facility management or technical maintenance solutions?

Pierre-Yves Dehaye: The building sector accounts for 16% of CO2 emissions in France. According to the Sustainable Real Estate Observatory, the carbon footprint of an office building amounts to 9 tonnes CO2 equivalent per square metre over its entire life cycle. Our facility management business is based on maintaining and operating buildings. The lighting, heating, climate control and water consumption required for buildings to function are naturally at the centre of the debate, along with their occupants’ lifestyles and uses. Our business units therefore have a role to play in accelerating our customers’ environmental transitions, both in terms of decarbonisation and the protection of natural resources. Plus, when we have teams of hospitality managers, we are in contact with our customers’ employees and hold the keys to understanding and acting on their behaviour and practices. This enables us to go further, thanks to our role in educating building users day to day (sorting waste, adhering to temperature setpoints, etc.).

How do you bring up the subject of decarbonisation?

P.D.: In a deliberately comprehensive way, through contractual commitments made on our own initiative with our customers. Effectively, the stance we took four years ago is to help our customers reduce their own emissions.

To be as effective as possible, we included customer Scope 1, 2 and 3 emissions from the outset. In addition to all the actions that affect Scopes 1 and 2 (energy efficiency, coolant fluids, etc.), this approach led us to address our own emissions, because that’s what helps reduce the customer’s Scope 3 upstream emissions. Our business units are making contractual commitments using low-carbon contracts, through which we are working to reduce our own emissions. They are also committing to so-called carbon-reduction contracts, through which they act on energy production, for example with heat recovery, and on the circular economy with the reuse of light fittings and thermostatic valves.

What tools do you have for putting this decarbonisation strategy into practice?

P.D.: There are various tools we can use within low-carbon performance contracts (LCPCs). Environmental QuickScan comes to mind. Based on a quick measurement of a customer or prospect’s specific emissions, it can recommend a decarbonisation plan linked to their emissions reduction trajectory.

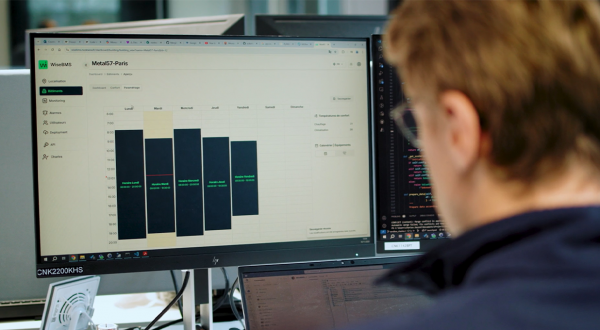

There’s also the CMS (Carbon Monitoring System), which is a tool for managing reduction commitments and highlighting the low-carbon performance measures implemented.

We also developed a tool based on ADEME and INIES data, which allows us to calculate the carbon footprint of the facility management contracts we fulfil for VINCI Energies customers. We call it the P2C (contract carbon profile) tool.

“We have a role and a responsibility in accelerating ecological transition”

Why did you develop this tool? What exactly does it do?

P.D.: This tool is great for educating our customers. The principle is simple: we identify sources of CO2, then the low-carbon performance actions, and we calculate the impact of these actions. As we use it with our customers, we raise their awareness of the benefits of taking decarbonisation further, of all working together to enhance our skills more quickly, feeding data into our calculation tables, entering our criteria and making the measures applied more and more effective.

P2C will be used in 100% of contracts by revenue in my area of responsibility by 2024, that is, around 2,000 contracts. This approach means we really have to revisit our business models. At the same time, we introduced a form of case-by-case carbon accounting comparable to our financial and economic management system. By including carbon commitments in our contracts, we highlight to our customers that emissions reduction can be a lever for cost savings and productivity, for them as well as for us.

What’s happening in areas other than decarbonisation?

P.D.: We have made inroads into the circular economy. Our business units have brought in a range of initiatives. We are now taking it to the next level, spreading and scaling up these practices to create an even more significant impact in terms of decarbonisation and protecting resources.

Our customers are becoming increasingly likely to think of repairing, reconditioning and buying second-hand. They are losing that reluctance to take the plunge. Platforms like Cycle Up and Proclus, to name the best-known, are gaining visibility and adding new products on a daily basis.

We also need to make progress on protecting resources, especially water and soil. In order to assess the impact that the fulfilment of our contracts has on natural resources, we have developed new functionality within P2C to calculate the materials-related impact.

We are advancing on all fronts, bringing as many stakeholders on board as we can.

12/12/2024