How can we improve data analysis performance in non-destructive testing during nuclear reactor shutdowns? The AUTEND project hopes to answer this question with an integrated AI solution.

The VINCI Energies subsidiary Omexom NDT Engineering & Services specialises in the design, approval and on-site operation of automated non-destructive testing (NDT) processes for critical components in EDF power plants. Its work involves performing and optimising nuclear site inspections, using methods such as ultrasonic and eddy current testing.

“This activity has made huge progress thanks to robotics, which is constantly increasing data acquisition rates for ‘signals’, which represent equipment defects,” explains Jean-François Herr, Business Unit Manager at Omexom NDT Engineering & Services. “But while there have been great strides in data acquisition, their analysis, which has to be performed in real time, is essentially still done by a human being.”

Symbolic AI

With the ongoing revival of nuclear now driving increases in the pace and number of nuclear site inspections, Omexom NDT Engineering & Services decided to facilitate and accelerate its analysts’ fieldwork by using artificial intelligence to automatically identify areas for closer inspection.

“Productivity in data analysis should increase 30%”

With this objective in mind, the business unit based not far from Valence, in France’s Drôme department, launched the AUTEND project: Automated NDT analysis. Omexom NDT Engineering & Services is managing this project in partnership with ALLONIA, a French startup with a leading AI platform, and the Acoustics Laboratory of the University of Le Mans (LAUM). ALLONIA is designing and developing the artificial intelligence platform and industrialising the business application, while LAUM is working to optimise and implement the data processing and analysis. The project has been running for two-and-a-half years (2022–2024), with support totalling €2.5 million from the French Ministry of Economics and Finance and Bpifrance under the France 2030 recovery plan.

“Given the security issues in the nuclear sector, AI cannot simply be used as a black box,” says Jean‑François Herr, “so we are using so-called symbolic AI, which helps us keep firm control over the process, unlike machine learning or deep learning, which can generate bias.” Additionally, hosting is in a secure cloud environment to ensure total control over information processing by users.

Productivity and quality

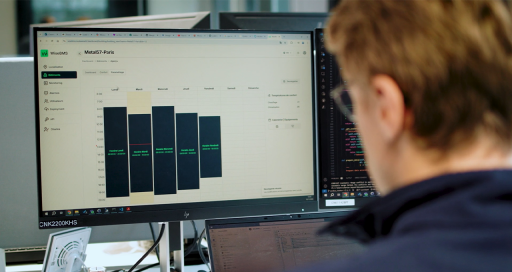

The first tests of AUTEND have been ongoing since September 2023, focusing on the analysis of data from eddy current inspection of steam generator pipes in nuclear power plants. The aim of the algorithm is to identify areas where the analysts should focus their work.

Jean‑François Herr explains: “We are hoping to improve in two areas: productivity in data analysis, which should go up by 30%, and quality, thanks to AI’s ability to perform additional checking on all cases entered previously.”

By increasing the analysis capacity and maintaining, if not improving, the reliability in interpreting the results, AUTEND will reduce the time required for these analyses and help adhere to the timetable for restarting the nuclear units.

“In time, we should be able to enhance the project by adding new AI modules,” says the Omexom NDT Engineering & Services manager, who hopes to apply the solution more broadly to other types of inspection, such as checking pipe welds in nuclear reactor control rod clusters. ALLONIA and LAUM are working to develop applications in various fields: cybersecurity to begin with, and then the inspection of carbon composites in the aerospace industry.

The project officially ends on 20 August 2024, when the Bpifrance finance program concludes. “But the AUTEND calendar doesn’t just end in the summer,” says Jean‑François Herr. “It will take time for EDF to approve this solution. Realistically, it could be operational by 2026.”

10/17/2024