Construction is attracting increasing scrutiny in connection with environmental transition. But there is relatively little focus on deconstruction, the more demanding but clearly more environmentally friendly alternative to demolition. This is a vital component in the circularity of a building.

Every year, the building sector in France generates around 45 million tonnes of waste, half of which comes from demolition sites. But what happens if we “deconstruct” rather than demolishing? This is the approach advocated by the REP PMCB (extended producer responsibility for building-sector construction products and materials) regulation, which came into force on 1 January 2023. Its aim is to prioritise the reclamation of materials over sending them to landfill.

“In a context where resources are becoming depleted, prices are rising, and supply chains are weakened, we need to promote the reclamation of existing fixtures through reuse or repurposing,” explains Nicolas Dumas, Environmental Project Manager at VINCI Energies.

Selective deconstruction is a process of “stripping” the load-bearing structure of the building in the gutting phase, retrieving interior fittings and sorting them in situ to keep them as intact as possible and maximise their potential for reuse or recycling.

Selective deconstruction

If everything than can be reused is to be reused, selective deconstruction is a way to progress pragmatically, step by step, or rather stream by stream.

The first step is to identify from technical batches the materials best suited to recovery and reuse, such as cables, cable trays, ventilation ducting and emergency lighting blocks.

“The electric cable category includes products used on a massive scale – kilometres or even tens of kilometres per site,” says Camille Thiriez, Innovation and Digital Solutions Engineer at Cegelec Nord Grand Projets. “They tend to be highly carbon-intensive (copper and plastic), fairly standard (80% of installations use two or three different types), and not generally altered following installation.”

“Circular thinking is not yet an instinct for our buyers. We must make it instinctive, and we are working toward that.”

For equipment that contains or transports water, and for refrigeration systems, the implementation of reuse processes becomes more complex in technical terms.

300 km of cable trays in Ile de France

The Ile de France area provides an example of what is possible. VINCI Energies Tertiaire Ile de France installs around 300 km of cable trays every year. “In 2022, we decided to launch an initiative to encourage circularity in this sector,” says Juliana Ton That, Ecological Transition Engineer at VINCI Energies Tertiaire Ile de France.

Starting with a few pilot sites, operating procedures were established for each product category, and outlines were drafted for the initial guidelines. VINCI Energies worked with building gutting specialists to define a number of criteria acceptable to everyone involved, compatible with careful removal and clean dissection.

Cable trays are refurbished and stored at RESO Services, a VINCI Energies business unit established three years ago and dedicated to worksite logistics, which has a 7,000 sq. metre warehouse in Blanc Mesnil (Seine Saint Denis department). Around a dozen collection sites and another dozen storage sites have since been added to the loop, and 1.5 km of materials have been installed.

Concentric circles

Volumes remain modest, which raises the question of acceleration. “We think that 1% of site materials and equipment are reused, but for technical batches, the figure is close to zero. We therefore need to move forward and work in concentric circles, incorporating other streams such as light fixtures, fan coil units and plumbing items,” argues Guillaume Graffin.

A former assistant technical director at Lefort Francheteau, Guillaume Graffin joined VINCI Energies Tertiaire Ile de France early in 2024 as a logistics and reuse engineering manager, with a mission to develop circular economy projects.

But scaling up means solving the supply-demand equation. Given its current embryonic state, the reuse market requires impetus from demand, which at least initially, must exceed supply.

“Circular thinking is not yet an instinct for our buyers. We must make it instinctive, and we are working toward that,” says Anne Taillefer, Purchasing Mission Manager at VINCI Energies France Facilities Sud Centre Est.

Training is being developed to help make this a reality. SEDDRe, a syndicate of almost 250 deconstruction, depollution and recycling businesses, is building a solution in this area.

Now compulsory in France for demolitions of buildings with a floor area greater than 1,000 sq. metres or which have housed one or more hazardous substances, PEMD (products, equipment, materials and waste) diagnosis could prove a valuable tool for accelerating deconstruction operations.

The aim of this diagnosis is to inform project owners of the nature, quantity and location of the various products, equipment, materials and waste present in the demolition zone, helping them to determine the reuse, recycling or recovery potential of the building’s interior fixtures.

Digital marketplaces

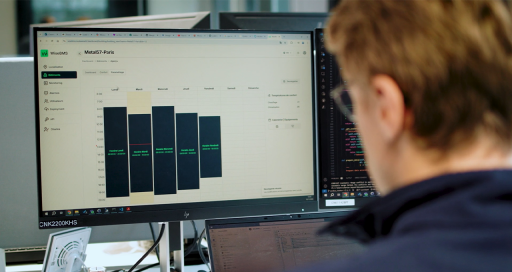

By helping forge connections between owners, contractors, architects, engineers, and demolition and construction companies, digital marketplaces such as Cycle Up or Reyuz are also essential to structuring the market. “Working on the data is one of the main prerequisites for moving selective deconstruction forward,” says Guillaume Graffin. “When stocks are limited to 800 ventilation duct items, it is perfectly possible to work with Excel spreadsheets and by exchanging emails. But as the catalogue expands, you obviously need different tools.”

06/13/2024