Virtual reality boosts efficiency and performance in the nuclear industry

Reading time: 4 min

No margin for error. In the nuclear industry, this watchword is a necessity. Virtual reality, a technology that boosts both efficiency and performance, is now being used to rule out error for the benefit of the sector.

Virtual reality models high-value-added projects in order to efficiently anticipate issues, from design defects to safety of personnel. The innovation ensures safety in the highly complex and constrained nuclear industry. “We work on outsized, one-of-a-kind projects with particular scales and complexities. Design reviews are undergoing a revolution driven by the fact that virtual reality can now be used in all types of projects,” says Michaël Brochier, CAD (computer-assisted design) engineering adviser at CEM Ingénierie.

“Virtual reality has brought about a paradigm shift by offering a new way to work in and address the requirements of the nuclear sector”

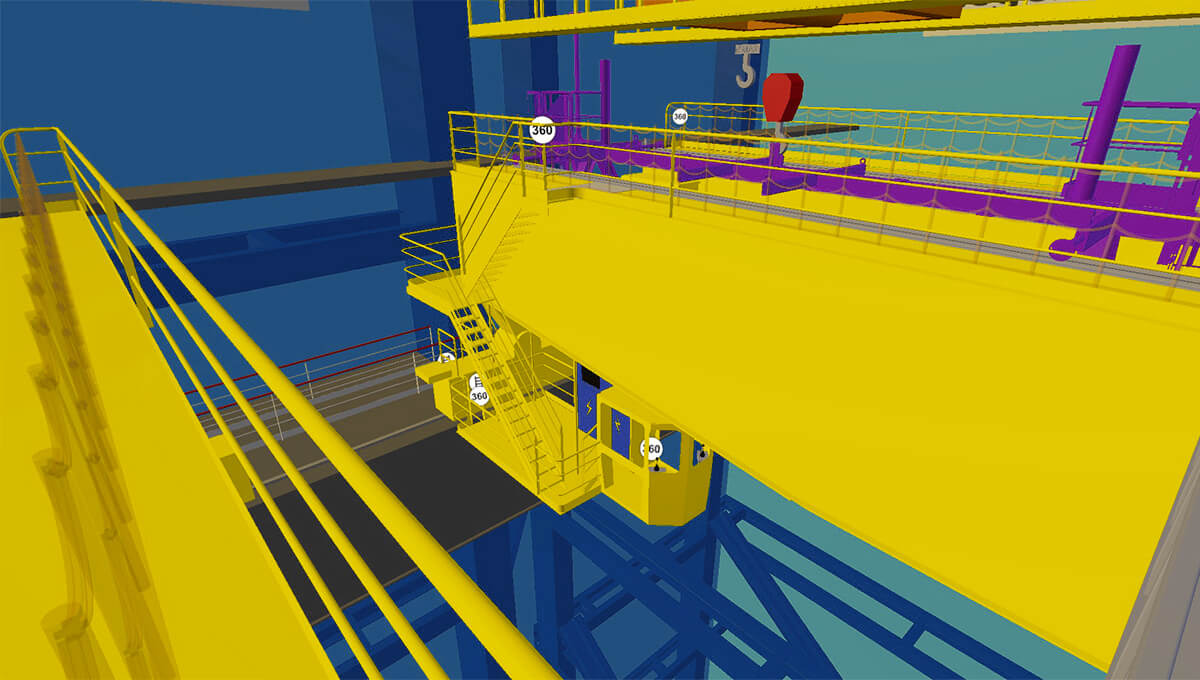

CEM Ingénierie, a VINCI Energies nuclear division company, worked with startup EAB Engineering to develop the collaborative virtual reality solution that it uses for customers such as EDF and ANDRA. “The model, derived from CAD, is becoming the digital twin of the nuclear facility,” says Michaël Brochier. Virtual reality makes it possible not only to use an avatar to move around the facility but also to expand the model by adding indicators, notes, and 360° photos. Everyone involved in the project, including the customer, can act and interact via a computer screen or virtual reality glasses.

Efficiency and performance

“Working within these virtual full-scale facilities enables us to better analyse our environment and the things we are handling. The purpose of the model extends well beyond inspection and design review. It has become a joint design tool,” says Michaël Brochier. “For example, one customer realised that the space provided for a wrench that opens a valve was far too narrow. We were able to save time by modifying and validating the change before work on the project got under way.” Displaying a facility on a 1:1 scale makes it possible to anticipate accessibility, ergonomics and feasibility of the work at a time when changes are least costly and time-consuming.

These simulations, carried out remotely from a computer or via a virtual reality headset, eliminate the need to physically move around the facility. They also make it possible to train worksite personnel before the start of work on the project. “We created a model for work to be carried out at a height of 78 metres in a place that was difficult to access,” says Michaël Brochier. “During training, I presented the work environment to the team, whose members were able to visit the facility ahead of time and move around freely in order to familiarise themselves with it and to review the aspects of their work that are relevant to their safety.”

For years, project engineers created drawings on paper, and then via CAD. Today they have begun to use virtual reality – a technology that as Michaël Brochier says “has brought about a paradigm shift by offering a new way to work in and address the requirements of the nuclear sector. I believe that a new revolution – very concrete and accessible to everyone, not just large groups – is under way.”

11/09/2017